The Core of Logistics: Grasping Pallet Significance

In the field of logistics, where efficiency and structure are essential, pallets play an indispensable role. Such flat platforms, commonly made of timber, plastic, or metal, serve as the foundation for shuttling and keeping goods. Their significance goes beyond mere functionality; they change the way products are managed, enabling the seamless movement of items through logistics networks and warehouses.

Understanding the significance of pallets is crucial for anyone involved in the logistics industry and shipping. They facilitate unloading and unloading, improve space utilization, and boost safety during transportation. By lifting goods off the ground, pallets also protect them from damage and contamination, making them a vital component in preserving product quality. As we delve deeper into the logistics environment, it becomes clear that pallets are more than a tool but a foundation that supports the entire structure of goods transportation.

Types of Pallets

In terms of pallets, they can be categorized into various types based on materials, design, and application. The most common type is the timber pallet, which is commonly utilized due to its strength and accessibility. Wooden pallets can support substantial weights and are commonly recycled repeatedly, making them a cost-effective choice for numerous companies. Their intrinsic characteristics also allow for easy repair, ensuring environmental responsibility in supply chain operations.

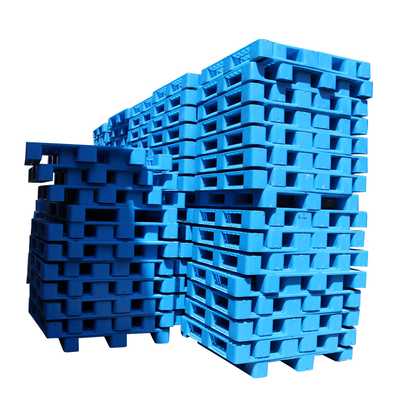

A widely accepted variant is the synthetic pallet, which has gained traction for its durability against wetness, agents, and vermin. These pallets are lightweight and simple to maintain, making them suitable for industries such as food and medicine. Additionally, pallets in tulsa do not splinter, reducing the risk of injury during transport, and they can be constructed to stack, optimizing storage during return logistics.

Finally, metal-based pallets, typically constructed from metal materials, are utilized in distinct scenarios where robustness and resilience are crucial. They are commonly found in robust sectors, such as the automotive sector and manufacturing, where they withstand tough environments and carry substantial equipment or devices. These metal options are also capable of being recycled, contributing to green initiatives in supply chain management. Every kind of pallet serves a specific role, highlighting the adaptability and essential function of pallets in the movement and storing of materials.

Transport slabs in the Logistics network

Transport slabs act a critical role in the supply chain by serving as a reliable base for layering and transporting goods. They allow the easy movement of products between various stages of the logistics network, from manufacturers to warehouses and ultimately to businesses. By providing a uniform platform, these platforms ensure that goods can be handled effectively by forklifts and hand trucks, reducing the time and work required for transferring.

In moreover to boosting efficiency, these platforms contribute to security within the supply chain. Properly secured loads on minimal platforms minimize the risk of loss during transport, which is vital for maintaining product integrity. This is especially important for delicate items or short-lived goods, where damage can lead to major losses. The use of pallets also helps in arranging products within storage facilities, ensuring that goods are easily accessible and reducing the risk of mishaps.

Additionally, pallets support inventory management practices. They allow for simple tracking and categorization of goods throughout the distribution system. By using multiple types of these platforms, such as standard, international, or throwaway, businesses can optimize their storage solutions to fit unique needs. Pallets not only simplify operations but also contribute to enhanced inventory counts, which is crucial for effective inventory oversight and forecasting.

Top Techniques for Pallet Handling

Effective pallet management is essential for improving the transportation and storage of goods. Routine assessment of pallets for wear guarantees that only reliable pallets are used. This helps to prevent likely product loss and maintains a safe working environment. Creating a routine for checking pallets can significantly reduce the risks associated with using damaged equipment.

Proper organization of pallets is yet another key aspect of effective pallet management. Well labeled holding areas help in monitoring the types and conditions of pallets available. Implementing a first-in-first-out method can also enhance inventory control and guarantee products are shipped in a timely manner. Overall, efficient pallet organization contributes to smoother logistics operations and improved resource utilization.

Educating staff on safe pallet handling techniques is essential. Employees should be instructed on the significance of pallets and how to safely handle and unload them. By reinforcing best practices in pallet handling, companies can lower accidents and ensure that goods are transported without harm. A well-trained workforce leads to overall better pallet management and increases the efficiency of logistics processes.